Best Fruit Grading Machines for Small and Medium Orchards in India

Top Fruit Grading Machines for Small and Medium Orchards in India”

Running a fruit orchard today isn’t just about growing high-quality produce — it’s about delivering consistency, efficiency, and market-ready fruits. For Indian farmers and packhouse owners, investing in a reliable fruit grading machine is no longer a luxury — it’s a necessity to stay competitive, reduce labor dependency, and meet export standards.

If you manage a small or medium orchard, this guide helps you explore the best fruit grading machines available in India, their features, capacities, and how to select the right one for your operation.

Why Fruit Grading Matters More Than Ever

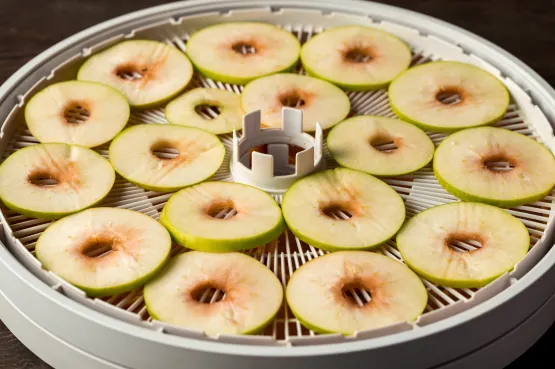

Before fruits reach retail shelves or export containers, they must be graded by size, color, and quality. Manual sorting is slow, inconsistent, and labor-intensive — especially when dealing with large harvests.

Modern automatic and semi-automatic fruit graders ensure:

- Uniform sorting and presentation

- Reduced handling damage

- Lower labor costs

- Higher sale value and export readiness

Whether you’re grading apples, oranges, kinnows, mangoes, or guavas, the right grader can dramatically improve profitability.

Types of Fruit Grading Machines for Small and Medium Orchards

Based on capacity, automation level, and features, here are the best options for small to mid-sized Indian growers:

In addition to custom manufacturing, Manufakture offers ready-made machines like Apple Graders, Egg Graders, Wrapping Machines, and Tobacco Cutting Machines. Each machine is designed for ease of operation, long-term reliability, and seamless integration into existing production lines.

Best for: Entry-level growers & small packhouses

Capacity: ~10–12 boxes/hour (approx. 1,000 apples/hour)

A compact, semi-automatic grader ideal for small-scale operations. It sorts fruits mechanically by size or diameter, offering an affordable and durable solution for orchard owners starting their post-harvest automation journey.

Key Benefits:

- Simple design, low maintenance

- Accurate mechanical sizing

- Minimal power consumption

- Easy to install and operate

Best for: Medium orchards needing cleaning + grading

Capacity: ~40 boxes/hour

This grader comes integrated with a dry brushing system that cleans the fruits while grading. It’s perfect for apples, oranges, and kinnows that require smooth surface cleaning before packing.

Key Benefits:

- Integrated brushing + grading

- Consistent surface cleaning for better presentation

- Ideal for mid-size operations

- Reduces manual labor and processing time

Best for: On-site or mobile operations across farms

Capacity: 40–50 boxes/hour

Grading: 15 grades (2 color, 7 size, 1 defect + configurable)

Compact yet powerful, this portable fruit grader combines automation, accuracy, and mobility. Designed for on-field or small packhouse setups, it’s easy to transport, set up, and operate.

Key Benefits:

- Fully automatic and portable

- Remote maintenance support

- Accurate grading across color, size & defects

- Perfect for growers managing multiple orchards

Best for: Medium packhouses & exporters

Capacity: 75–85 boxes/hour

For those ready to upgrade, the Vision Grading Plant offers advanced camera and AI-based grading by size, shape, color, and defects. While it’s used in larger plants, compact configurations make it ideal for medium-scale setups too.

Key Benefits:

- Vision-based grading accuracy (±1 mm)

- Handles multiple fruit types

- Supports washing, waxing & auto-tray packing

- Designed for export-grade consistency

How to Choose the Right Fruit Grading Machine

When comparing fruit grading systems, consider the following factors:

- Capacity Needs:

Estimate your average daily harvest volume to match machine throughput (in boxes/hour). - Type of Produce:

Choose a grader that supports your crop — apples, kinnows, mangoes, or mixed produce. - Automation Level:

- Semi-Auto: Ideal for low-cost, smaller operations

- Automatic / Vision-Based: Suitable for higher precision and export readiness

- Available Space & Mobility:

Compact graders or mobile units are perfect for farms with limited area or multi-location setups. - Budget & ROI:

Consider long-term savings on labor, improved quality, and faster processing speeds.

Why Indian Growers Prefer Our Grading Solutions

Our range of fruit grading machines is designed for Indian farm conditions — durable, easy to maintain, and suited for various fruit types. From small farmers in Himachal and Punjab to commercial packhouses in Maharashtra and Gujarat, our graders have proven reliability and performance.

Every model offers:

- High accuracy & gentle fruit handling

- Food-grade belts & materials

- Customizable grading configurations

- Remote maintenance & technical support

Final Thoughts

For small and medium orchards, upgrading to a mechanical or vision-based fruit grader is one of the most effective ways to improve productivity and fruit quality. With India’s growing demand for uniform, export-ready produce, investing in a reliable grader is a step toward long-term profitability.

Every model offers:

- High accuracy & gentle fruit handling

- Food-grade belts & materials

- Customizable grading configurations

- Remote maintenance & technical support

Ready to Find Your Perfect Grader?

Explore our complete range of Fruit Grading Machines for Apples, Oranges, and Kinnows — designed to match every scale, from small farms to industrial plants.

Every model offers:

- High accuracy & gentle fruit handling

- Food-grade belts & materials

- Customizable grading configurations

- Remote maintenance & technical support

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.